By Apek Mulay, Sr. Analyst

Reproduced from SemiWiki.com

It is an open secret that, for a variety of reasons, the U.S. manufacturing base has sharply deteriorated over the past three decades, and the semiconductor industry is no exception. In fact, this industry may have suffered harder than some other American enterprises. The purpose of this paper is to explain the causes of this decline and offer some commonsense economic policies that may lead to the industry’s revival.

In the microelectronics area a semiconductor fabrication plant (also called a fab) is a factory where such devices as integrated circuits are manufactured. A business that operates a semiconductor fab for the purpose of fabricating the designs of other companies, such as fabless semiconductor companies, is known as a foundry. If a foundry does not produce its own designs, it is known as a pure-play foundry. As of today, the semiconductor industry follows multi-national corporations’ (MNCs) business model based on globalization, as shown in figure 1 below. Following WWII the United States pursued globalization, believing that American firms would be able to capture foreign markets, but the opposite happened. Other nations imported technology from gullible American companies, and, with their low real wages, out-competed U.S. firms all over the world. The rest is history. By now many American industries have disappeared, while most others have shrunk, resulting in a loss of jobs and stagnant wages.

When The Great Recession struck in 2007, the lingering weakness of the American economy, so far ignored by experts and the government, came to the surface. The present state of the US economy has been very discouraging to millions of Americans who are unemployed. This jobs crisis is a result of diminished purchasing capacity of consumers due to U.S. trade and macro-economic policies. With decreased exports and increased imports and the high cost of maintaining US war fronts abroad, the budget deficit has been increasing over the years, causing serious concerns and political tensions. Additionally, counterfeit electronics from abroad have raised national security issues.

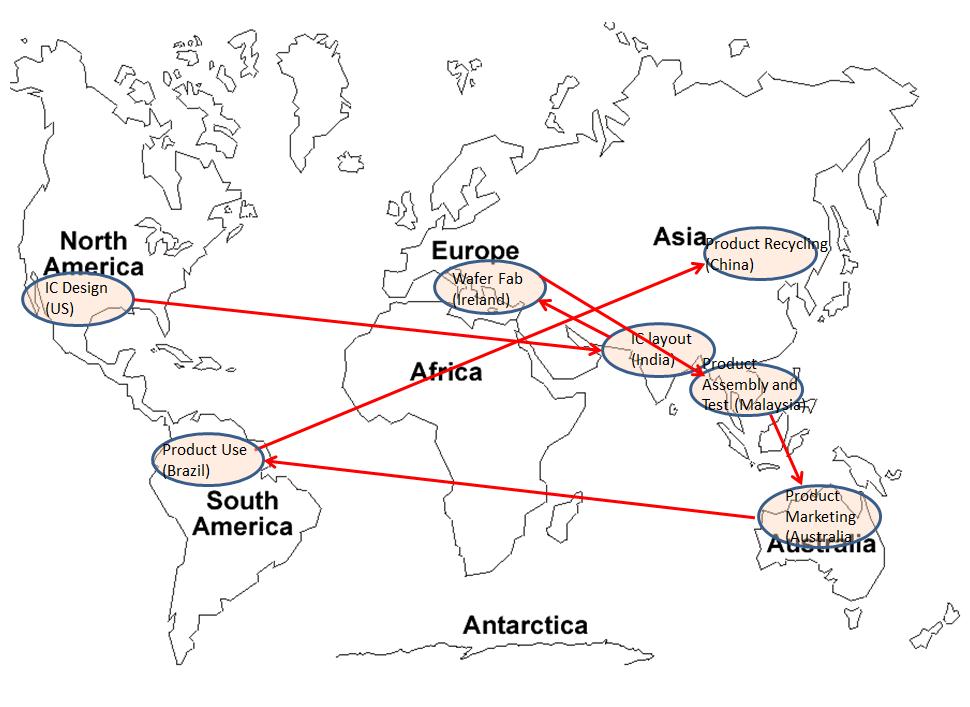

Figure 1: Business Model of MNCs based on Globalization

As shown in this figure the MNCs have spread their semiconductor production operations across the globe when it comes to design engineering, test engineering, manufacturing, Sales and marketing, Packaging and Assembly, etc.

Since the 2007 recession, the semiconductor industry has observed flat growth in its revenue and many small businesses have experienced a slowdown. Such stagnation has been analyzed in my recently co-authored article ‘Revival of US Electronics and Semiconductor Industry and Mitigation of Counterfeit Electronics through Macro-Micro Economic Policies. Here I offer new ways to transform the entire semiconductor industry, enabling it to have high profits and steady growth. This model would help position this sector to break away from its usual boom-and-bust cycles and generate high profits in years to come.

The proposed business model is designed to (i) help restore a balanced economy without having to rely on overseas investment or foreign debt, (ii) establish a free-market economy where supply and demand of goods rise and fall automatically with minimal government intervention, (iii) solve the problem of unemployment and hence excessive government spending that leads to budget deficits, (iv) help the semiconductor business be at the leading edge of technology through sustainable capital investments, (v) ensure a competitive business environment which would stimulate the growth of small businesses, and so on.

A balanced economy is critical to take the global semiconductor industry to the next level of innovation and financial success. An economy is considered to be balanced when there are no trade deficits and no budget deficits. Such an economy would increase domestic consumer purchasing power by letting wages of workers to catch up with their productivity, thus establishing an Economic Democracy.[1] An economy is considered to be balanced when the supply of the goods from producers and their demand from consumers grow and fall in the same proportion. Such an economy does not lead to overproduction, nor does it lead to any underutilization of resources. The wages of the consumers contribute to their demand and the productivity of the workers contributes to their supply. A balanced economy ensures that wages catch-up with productivity, which results in demand to catch up with the supply. As workers in a balanced economy work hard by being productive at the jobs, the wages of these workers also grows and hence these workers as consumers can generate greater demand. This enables producers to manufacture more goods to meet the ever growing needs of the consumers due to higher consumer purchasing power. Here there are no economic downturns, because consumer demand is always sufficient to match producers’ supply.

In addition to a balanced economy we also need a decentralized supply chain, which increases co-operation among businesses, decreases wealth concentration in the economy, improves efficiency and customer satisfaction.[2] Macroeconomic reforms towards wholesome decentralization of Fabless business would boost the growth of several small fabless firms in an economic sub-system. Only with a decentralized supply chain does an individual player flourish.[2] Hence, the decentralized supply chain leads to smaller organizations and a lower probability for mergers and acquisitions. A decentralized supply chain leads to higher co-operation among entities in an industry. By placing a higher value on building a relationship with the end customer, decentralization leads not only to overall customer satisfaction, but also to healthier long-term relationships with end customers.[2]

A Three-Tier Model

I propose a three tier model for the robust growth of Fabless semiconductors based on Economic Democracy with Economic Decentralization.[3] The entire semiconductor Industry should be split into economic sub-systems. These sub-systems should be based on the availability of the necessary raw materials. This model is based on what is known as Progressive Utilization Theory or PROUT, which was put forth by Shri Prabhat Ranjan Sarkar in 1959; Prout has been further analyzed by the world famous economist Professor Ravi Batra.[6]

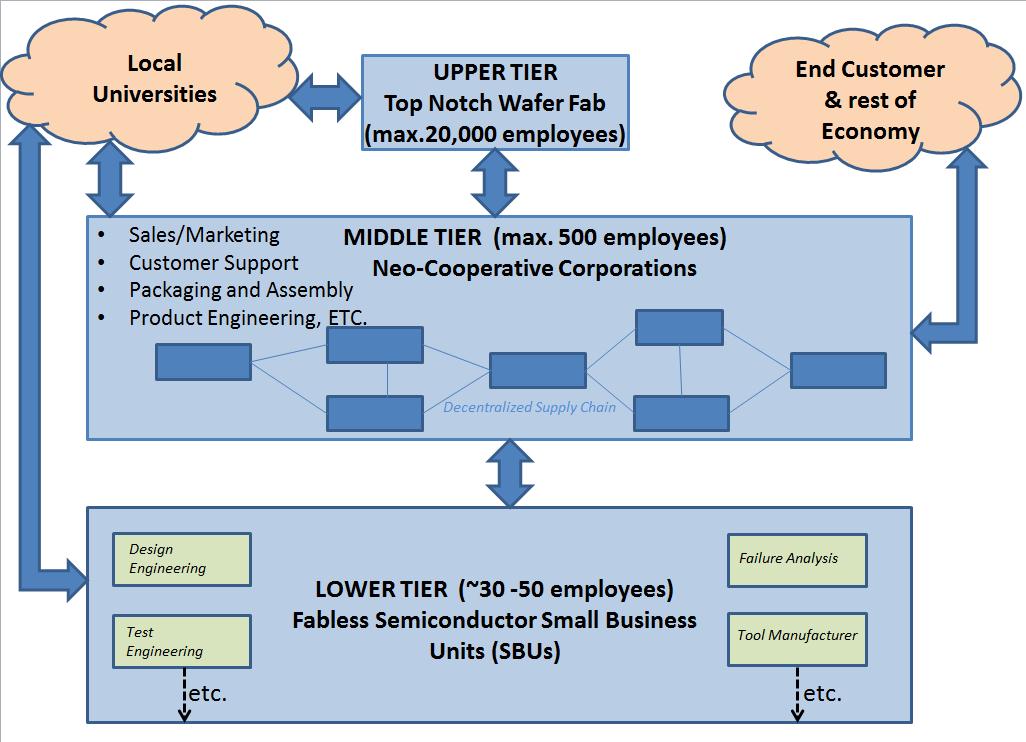

Figure 2: A Three Tier business Model for Semiconductor Industry

As shown in the figure the upper Tier is a top Notch Wafer Fab and Fabless small businesses are a lower tier. The middle and most important tier have neo-cooperative corporations which have exchange relationships in a decentralized supply chain. The Middle industrial tier connects the other two industrial tiers with rest of the economy.

Upper Tier – Semiconductor Manufacturing from Top Notch Wafer Fab

A top notch wafer fab needs an investment larger than a nuclear reactor. In 2013 the cost of building the next generation wafer fab was estimated at over $10 billion.[4] The location of wafer fab should be strategic to have ready availability of all necessary raw materials needed for manufacturing. The local government should build necessary infrastructure like domestic or international airport, good transportation facilities, good infrastructure, etc. for a smooth delivery of the goods to end customers. This would ensure the growth of smaller and medium size businesses, which would cater to that fab. Any infrastructure investment would be a long term investment to attract other businesses.

In order to have a balanced economy, the official monetary policy should be such that wages keep up with labor productivity.[1] Since workers’ wages contribute to consumer demand and workers’ productivity contributes to the supply of goods, when wages catch up with productivity, supply and demand grow and fall together.[1] Hence, it is important that company profits are first shared among the employees in proportion to their productive contributions and then later with outside investors. In order to ensure that wages catch up with productivity, there should be special incentives offered to highly productive employees. This portion of profits should be allocated to those employees who are much more innovative and productive than others. The remaining profits, if any, should be shared with the private investors as return on their investments. It is very important for an economy to first ensure that wages catch up with productivity to maintain a rational distribution of wages. This would also eliminate any economic imbalance which might result as a result of huge wage disparities.

While company profits should be shared across the board in proportion to productive contributions of employees, these fabs, although government backed, should have complete autonomy to lay off lazy and un-productive employees. This model would ensure that the wafer fab remains a top-notch fab and is also at the fore-front of innovation. Additionally, it would rectify the inefficiencies that may have existed in government run businesses. Similarly, by letting the employees’ wages catch up with their productivity, it would ensure a high consumer purchasing power in economy.

For the semiconductor industry to be financially successful, it is critical that money circulates in the economy and does not remain idle in bank vaults or other forms of valueless hoardings. To make this feasible, it would be best for a wafer fab to offer retirement schemes to its employees such that employees can invest some of their income towards the growth of their company by purchasing company shares. In this manner a wafer fab can raise much needed capital, while its employees become part-owners.

This model has two benefits. Since employees own some shares of the Wafer fab, they would work hard towards the success of the foundry. In economic downturns, these wafer fabs would prefer to share losses by taking across-the-board wage cuts or by cutting work hours of workers rather than laying them off. This would essentially maintain balance in the supply of goods to their demand. Additionally, since massive job losses due to layoffs could be minimized in economic downturns, it would also minimize government spending and hence budget deficits for offering unemployment benefits for laid off workers.[1]

In order to engender accountability and transparency in employees’ performance reviews, individual departments inside Wafer Fabs should be decentralized so that different engineering teams are grouped into smaller teams which elect their respective representatives onto the corporate management board in a democratic way. This would enable employees to voice their concerns directly to the management through their representatives. These employee representatives on management board would work with other members of the management board to ensure that majority of decisions are taken by board, in the best interest of employees and hence of the company, thereby engendering a healthy relationship between the employees and management.

A good wafer fab should also collaborate with local universities by offering co-operative internships to engineering students and technicians. This model would enable a foundry to offer challenging thesis projects to students pursuing Masters in Engineering through co-operative internships. The Wafer Fab should also offer doctoral research fellowships or internships so that these doctoral students would essentially work for the company at a fraction of the salary of regular research employees; this is the most economical way to fund R&D.

Local Universities and foundries can also collaborate to arrange a mechanism[5] by which:

- Doctoral students’ research can be sponsored by this ‘university-companies conglomerate’, and then the resulting technologies (developed by the doctoral students) are spun off into new companies which are partly owned by this ‘conglomerate’ and partly by the doctoral students and their supervisors. They would become future entrepreneurs of semiconductor industry and be a part of Lower Tier of this business model. Such conglomerates open up equal opportunity for material and intellectual advancement to all students.[8]

- The ‘doctoral students owners’ are then free to employ their master’s degree graduates in their companies, and implement a system of employee profit-sharing. This would not just help students with financial aid, but also help the semiconductor foundry get its R&D work done from by the doctoral students.

Lower Tier – The Fabless Semiconductor Businesses

An established top notch wafer fab would also create local businesses, which provide necessary tools, test equipment, engineering services, etc. for smooth functioning of wafer fab. These providers of different services, in addition to the fabless semiconductor businesses, would form Lower Tier of this 3-Tier business model.

In order to ensure sufficient job creation in the local economy, the fabless industry should undergo wholesome decentralization when it comes to offering these engineering services. Small Business Units (SBUs) should offer engineering services such as Circuit design engineering, Circuit layout engineering, test development engineering, Failure Analysis, Tool Manufacturing and Maintenance, etc.

Each engineering service provider should work as an independent SBU with a maximum of 30-50 employees in each business unit. These SBUs should comply with anti-trust laws which should be strictly enforced to avoid Mergers & Acquisitions (M&A). Some of the existing Fabless corporations are too big and they use their hefty profits to acquire small businesses. These M&As restrict competition, which has resulted in monopoly Capitalism instead of the free- market- capitalism in the semiconductor industry. To avoid this opportunistic behavior the existing shares of all major corporations should be given to the employees of these corporations in proportion to their productive contributions. The next step should be to decentralize the fabless companies and make each individual business unit function independently. This means the design engineering team would become an independent business; so would the product engineering team, customer quality engineering, reliability engineering and so on. The respective businesses would operate at either Lower tier or Middle tier depending on their operation as shown in Figure 2.

The Integrated Device Manufacturers (IDMs) which are currently privately owned and are not able to manufacture the latest technology should also split their fab and fabless businesses in accordance with the previously mentioned approach. The old fabs could function as Tier 1 wafer fabs for analog chips which do not need cutting edge transistor technology and the fabless businesses in these IDMs could be split into independent businesses to join either the Middle Tier or the Lower Tier, based on their business type. Similarly, large tool manufacturing corporations should be broken into SBUs so as to enable them to operate as independent small businesses. The wafer fab should give equal opportunities to all SBUs to compete for business to usher in a competitive free market economy. This would encourage new entrepreneurs to start their own businesses to provide various engineering services to the Principal Wafer Fab Company, and hence promote innovation. The Middle Tier of the 3-Tier model should act as a medium to offer these services to wafer fab and should also act as the most important sector, which links the end customer (or user of electronic products and services) to upper and lower tiers of the semiconductor industry.

All engineering departments involved at the pre-silicon and post-silicon stages should have a healthy competition with one another. This would enable the end customer to get products manufactured at significantly lower costs. Such a decentralization of the Fabless business would provide most innovative designs of new products and also eliminate any chance of large firms exercising their monopoly power.[2]

Although the quality of products within some of the economic sub-systems would be not as great as those of other economic sub-systems, by having bench marking and knowledge sharing through International Symposiums, Publications and discussion forums like Semiwiki, EBN, etc. it would be possible to gradually improve the quality of products and services for the entire global semiconductor industry in all subsystems. This is the only way that the global semiconductor industry could prosper along with the growth of regional semiconductor industry. In order to boost the development of more Fabless SBUs for new entrepreneurs, the local government should help set-up SBU associations all over the economy which could lease equipment and tools for setting up small businesses like Failure Analysis labs which require significant capital investment.

Middle Tier – The employee sponsored neo-cooperative Corporate Sector

The Middle tier should include those semiconductor businesses which work directly with end customers. This sector should include relatively mid-size corporations with a maximum of 500 employees. This sector would interface directly with end customers, the Upper business Tier and the Lower business Tier. It would consist of co-operatively managed semiconductor companies, where the majority of company assets are owned by company employees. All corporations in this tier should have exchange relationships as a decentralized supply chain. In a decentralized supply chain, individual units make decisions based on local information. In such a system, it becomes easy to incentivize players to act in co-operation, making entire supply chain efficient.[2]

The Sales and Marketing division would be able to get feedback on the demands from local customers and draft customer specifications to manufacture customized electronic gadgets based on the needs of the domestic economy. This Middle tier team would also interface with Lower tier SBUs, e.g. design engineering in order to develop customized electronic products as shown in Figure 2.

The packaging and assembly of chips would also be done in this tier. This tier would work on voluntary cooperation among corporations in the Middle. However, those corporations that follow the model of employee sponsored corporations should be given tax incentives in order to attract the other players in the middle tier to follow the model of employee owned corporations. Majority shares of mid-size corporations in the Middle tier would be owned by employees for them to have a stake in the success of their business. Since the middle tier interfaces with both Upper and Lower Tiers of economic sub-system, it would be managing Supply and Demand of consumer electronics to maintain a balanced economy.

There are many advantages of having the Middle Tier in the Semiconductor industry. If neo-cooperative corporations in this sector notice that customer demand is falling, then they would be able to communicate with the Wafer fab at Upper Tier and the fabless business unit at lower Tier to avoid overproduction of silicon. Both the upper and lower tier could utilize economic downturns to either cut work hours of their employees, to retrain their employees or to concentrate on R & D activities. In the present global economy, due to the absence of the middle tier, whenever there is a stock-piling of inventories in a wafer fab; the fab lays off its employees because of poor economic demand.

With this Middle tier, the neo- cooperative corporations would be able to adjust the Supply and Demand of electronics with a cooperative action of producers and consumers. Additionally, the Middle tier would provide an accurate real time estimate of consumer demand, thereby providing a feedback to upper and lower business tiers about customer requirements and demands in order to provide a better customer service.[2]

Another advantage of this 3-Tier Business model would be ‘Parallel Processing’ which is very much needed as the industry is progressing to adopt advanced transistor technology nodes. The Middle level corporate sector would be able to negotiate a good price for pre-silicon and post silicon services and get the work started simultaneously with shorter life cycles. This way manufacturing cycle time could be reduced and manufacturing costs would also decline significantly. Since the majority of corporate shares of this sector are owned by employees, there would be shared growth and prosperity, which would minimize concentration of wealth in the hands of the few.

When economy grows, the wages of all employees would also grow, leading to the growth of the overall economy. The growth of the overall economy would also grow stock values of the corporations and hence the year over year profits of all the employees in these corporations (and not just CEOs, CFOs and board of directors) would also grow steadily. When the economy slows down, the corporations would reduce work hours across the board to avoid job cuts due to layoffs. This way the problem of unemployment would be permanently solved. Additionally, since the Middle Tier is employee sponsored corporate sector, all majority corporate decisions are made democratically without any kind influence from non-employees.

A decentralized supply chain in Middle Tier would generate high growth and employment without large scale migration from rural to urban centers. This would avoid urban congestion and myriad related problems. Such supply chain also engenders better customer satisfaction by guaranteeing product delivery through an alternate route in cases where the regular supply chain is disrupted by unforeseen events like natural disasters and social or political instability.[2]

This 3 tier business model for global Semiconductor industry would wholeheartedly accept automation in the industrial sector. Due to the use of new machines labor productivity would grow exponentially because of which the supply of goods into the economy would also grow. In order to maintain the economic balance, consumer demand would have to match the growth in Supply. In such a scenario the co-operative sector would be able to meet the required production target with fewer work hours but pay its workforce a higher salary in proportion to their higher productivity resulting from the use of machines. This would give sufficient time for employees to pursue further education, vocational training and help the workforce to keep up-to-date with the desired skills needed to continue their careers in ever progressing and rapidly advancing semiconductor industry.

This business model would make contributions to completely automate production of semiconductor chips from the beginning to the end which is often referred to as “Lights-out-fab”.[9] Such a business model would not only lead the fabless semiconductor industry to the next level of innovation and financial success, but would also act as a model for other sectors in the economy leading to a vibrant growth of regional and national economies.

References

[1]See Ravi Batra, Common Sense Macro Economics, Liberty Press, Richardson, Texas, 2004 and 2012, for this definition. Also see A Mulay, A Failure Analysis of the US Economy, Truthout.org (2 March 2013). http://www.truth-out.org/news/item/1…the-us-economy

[2]Apek Mulay, Decentralize to Improve Supply Chain Efficiency, EBN (11 October 2013). http://www.ebnonline.com/author.asp?…c_id=268703&#!

[3] P R Sarkar, “Decentralized Economy”, PROUT in a Nutshell, Part 21, Pgs. 32-42, Ananda Marga Publications (1959).

[4] Wafer fabrication, From Wikipedia, the free encyclopedia http://en.wikipedia.org/wiki/Wafer_fabrication

[5] Apek Mulay and Dhanjoo Ghista, “Globalization of Semiconductor Manufacturing Industry From Deception to Reformation Towards Recovering US Macro-Micro Economic Losses”, Electronics.ca Research Network (24 June 2013).http://www.electronics.ca/presscente…ses/Page1.html

[6] Ravi Batra, “Prout: The Alternative to Capitalism and Marxism”, University Press of America (January 1983) Also see his books, Greenspan’s Fraud and The New Golden Age, both published by Palgrave-Macmillan, for an analysis of economic democracy and the importance of narrowing the wage-productivity gap to maintain a balanced economy.

[7] Apek Mulay and Dhanjoo Ghista, “Revival of US Electronics and Semiconductor Industry and Mitigation of Counterfeit Electronics through Macro-Micro Economic Policies, towards (i) Recovery from Trade and Budget Deficits and National Debt, and (ii) Engendering US Economic Growth”, Electronics.ca Research Network (29 October 2013).http://www.electronics.ca/presscente…h/Page1.html#!

[8] Ulrich Naeher, Sakae Suzuki, and Bill Wiseman, “The evolution of business models in a disrupted value chain”, McKinsey and Company (Autumn 2011). http://www.mckinsey.com/client_servi…ed_value_chain

[9] Semiconductor fabrication plant, From Wikipedia, the free encyclopedia http://en.wikipedia.org/wiki/Semicon…rication_plant